The Word of God Holistic Wellness Institute

"Helping The World DISCOVER THE WAY of LOVE!"

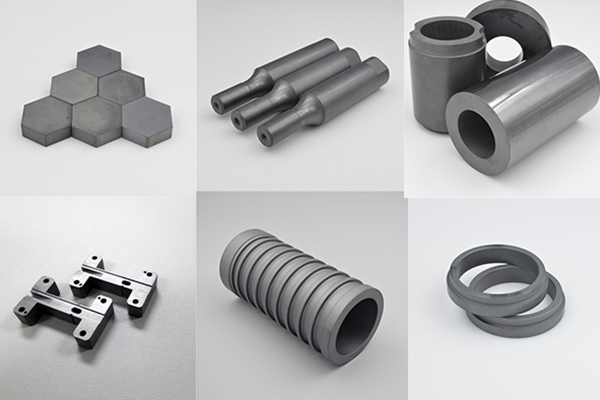

Defining Silicon Carbide Ceramic: An Expert Overview

Silicon carbide ceramic (SiC) is a sophisticated ceramic composed of silicon and carbon. Naturally, it appears as the rare mineral moissanite. Since 1893, synthetic SiC powder has been widely manufactured primarily for abrasive applications. By sintering silicon carbide grains, extremely hard ceramic materials can be produced.

The swift advancement of modern national defense, nuclear power, aerospace, automotive, and marine engineering sectors has heightened demands for materials. This creates an urgent need to develop diverse new high-performance structural materials.

Silicon carbide ceramic materials exhibit exceptional properties including high-temperature strength, excellent wear resistance, low thermal expansion, superior hardness, thermal shock resistance, and chemical corrosion resistance. These attributes make them extensively applicable across automotive, machinery, chemical industries, environmental protection, aerospace, information electronics, energy, and beyond. As a result, silicon carbide has established itself as a vital structural ceramic with outstanding performance in numerous industrial sectors.

In particular applications, silicon carbide ceramics are extensively utilized as corrosion-resistant containers and pipelines within the petrochemical sector. They are also effectively employed in bearings, cutting tools, and mechanical seal components in the machinery industry. Furthermore, silicon carbide is regarded as a leading candidate for future manufacturing of gas turbines, rocket nozzles, and engine parts in aerospace and automotive fields.

Fundamental Characteristics of Silicon Carbide Ceramics

Chemical properties

At an oxygen reaction temperature of 1300 ℃, a protective silicon dioxide layer forms on the surface of silicon carbide crystals. As this layer thickens, it inhibits further reaction of the silicon carbide beneath, granting the material notable chemical resistance. Silicon carbide demonstrates strong acid resistance but comparatively weak alkali resistance, attributable to the properties of the silica protective film.

Physical properties

Various silicon carbide crystals share a similar density, typically around 3.20 g/cm³. Silicon carbide exhibits a Mohs hardness of 9.5 and a Knoop hardness ranging between 2670 and 2815 kg/mm², surpassing corundum in abrasives and ranking only below diamond, cubic boron nitride, and boron carbide. With excellent thermal conductivity, strong resistance to thermal shock, and low thermal expansion, silicon carbide ceramics are considered superior refractory materials.

Electrical properties

At a constant temperature, industrial silicon carbide ceramic functions as a semiconductor exhibiting impurity conductivity. In high-purity silicon carbide, internal resistance decreases as temperature rises. Additionally, the conductivity varies depending on the types of impurities present in the silicon carbide.

Good hydrophilicity

Silicon carbide (SiC) is widely recognized as a compound characterized by strong covalent bonding. Pauling's electronegativity calculations indicate that the Si-C bond exhibits only about 12% ionic character. As a result, SiC possesses high hardness, a substantial elastic modulus, and excellent wear resistance. Notably, the silicon dioxide layer that forms on its surface during oxidation acts as a barrier, limiting oxygen diffusion and thus reducing the oxidation rate.

Views: 5

-

Comment by yserenaw on Wednesday

-

Mainspring technology continues to advance although, as with many other aspects of mechanical horology, improvements tend to be incremental rather than revolutionary. Mainspring production nowadays, thanks to the precision necessary in modern watchmaking, as well as the complexity of the link alloys link and metallurgy used, link is largely automated. There are however occasionally signs that more dramatic advances might be possible.

link

Comment

© 2025 Created by Drs Joshua and Sherilyn Smith.

Powered by

![]()

You need to be a member of The Word of God Holistic Wellness Institute to add comments!

Join The Word of God Holistic Wellness Institute